Carbon fiber is a material that has revolutionized the automobile industry with its strength-to-weight ratio and aesthetic appeal. In this article, we will discuss the various uses of carbon fiber in the automotive industry, its advantages, and the future of this material in the industry.

Carbon fiber reinforced polymer (CFRP) is a composite material that is made up of carbon fiber and a polymer resin such as epoxy. The high strength-to-weight ratio of carbon fiber makes it an ideal material for use in the automobile industry. Carbon fiber components are not only lightweight but also strong, which makes them perfect for high-performance automobiles.

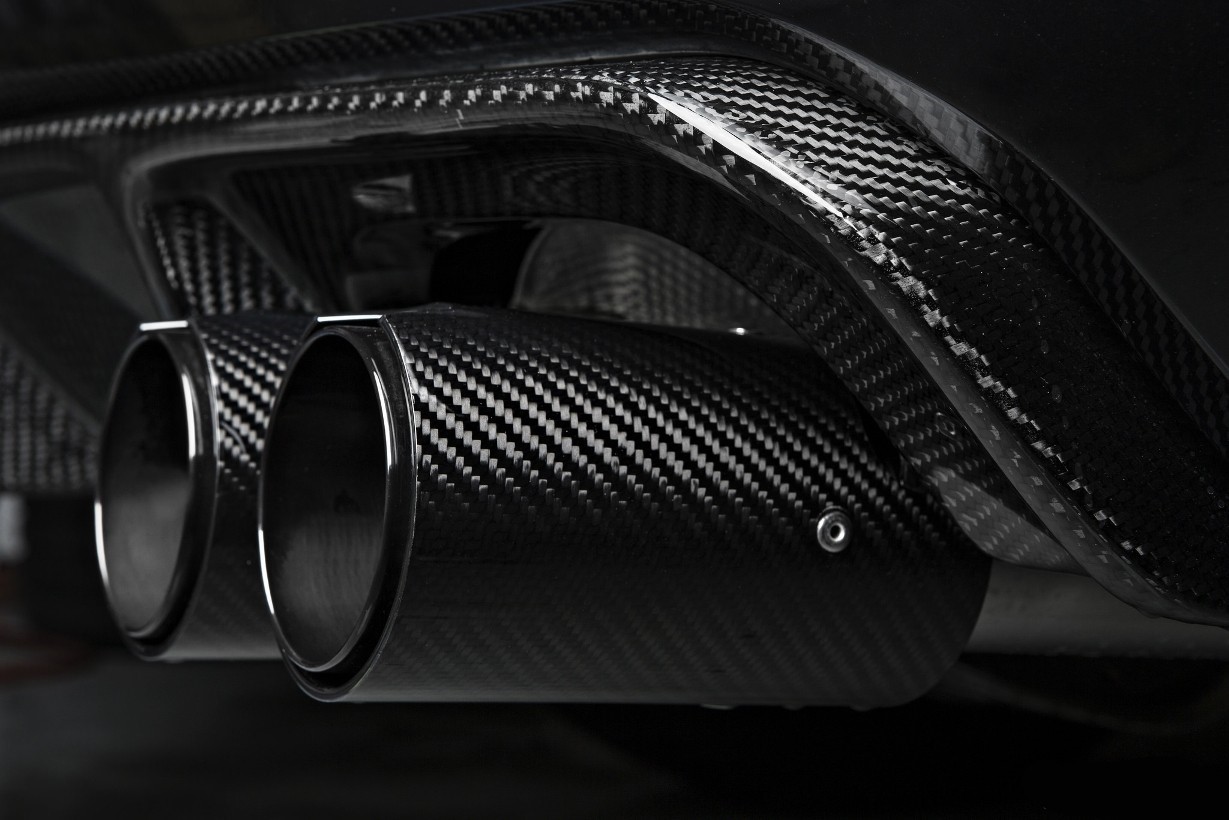

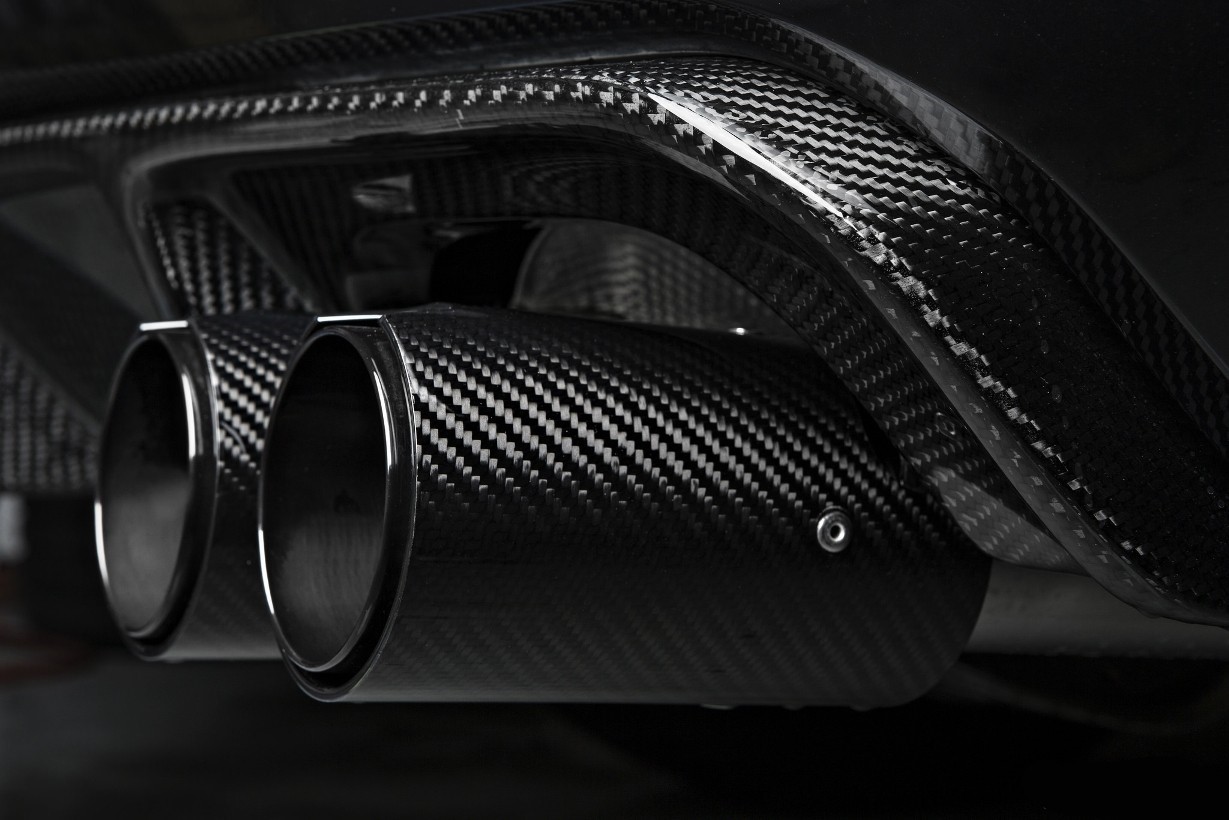

Parts and Components

Initially, carbon fiber was used only in high-end cars, supercars, and expensive racing models in smaller parts and components to gain speed advantages. However, the use of composite materials has increased drastically, and many cars now use carbon fiber in their body construction as well. The lightweight build of cars using carbon fiber leads to a gain in fuel efficiency, and a 10% reduction in weight can save up to 6-8% of fuel in automobiles.

Feels Light and Looks Sleeker

The use of carbon fiber not only provides better performance but also enhances the appearance of automobiles. With the benefit of quick acceleration and higher top speeds, the material adds a smoother and sleeker touch to the appearance of automobiles. This has led to several cosmetic applications of the material in the industry.

Carbon Fiber and Electric Vehicles

The emerging new breed of electric cars relies heavily on carbon fiber components. Carbon fiber backs fuel efficiency and increased battery life, which perfectly suits the objectives of the electric car industry. Both technologies are forward-looking and can benefit from complementing each other. Additionally, their selling point of being futuristic is perfectly streamlined.

Advantages of Carbon Fiber in the Automotive Industry

The use of carbon fiber in the automotive industry offers various advantages. The material is extremely lightweight, which improves the fuel efficiency of automobiles. Carbon fiber is also strong and durable, which makes it ideal for high-performance automobiles. Moreover, it has excellent thermal conductivity and is resistant to high temperatures, which makes it suitable for use in engines and other high-temperature applications.

Manufacturing Challenges

One of the major challenges of using carbon fiber in the automotive industry is the high cost of production. Carbon fiber production is an expensive process, and the material itself is costly compared to traditional materials such as steel and aluminum. However, with advancements in manufacturing processes, the cost of production is expected to decrease, making carbon fiber more accessible to mainstream automobile manufacturers.

The Future of Carbon Fiber in the Automotive Industry

The future of carbon fiber in the automotive industry looks promising. With automakers realizing the benefits of using composite materials, the demand for carbon fiber is on the rise. As car companies intend to use more carbon fiber in body panels, the demand for the material is expected to increase even further. The performance of existing cars using composite material components has proved their absolute advantage in speed and fuel efficiency as well as strength to withstand crash conditions.

With continuous advances in carbon fiber technology, the use of the material is expected to become more widespread. We can expect to see the widespread use of carbon fiber in all kinds of automobile parts as soon as high-volume production at lower costs becomes a reality through faster manufacturing processes. As price reduction is the only prerogative, it is expected that the use of carbon fiber in cars will become more widespread than ever before.

In conclusion, the use of carbon fiber in the automotive industry has revolutionized the way cars are built and designed, including the development of advanced telescopic systems. Its lightweight yet strong properties have not only improved fuel efficiency but also enhanced the overall performance of automobiles, especially when it comes to suspension and steering systems. With the increasing demand for smoother rides and more advanced vehicle control, carbon fiber telescopic systems are expected to play a significant role in the future of automotive engineering. As the technology continues to advance, we can expect to see more widespread use of carbon fiber in mainstream automobiles, including the integration of telescopic systems for better handling and maneuverability. The automotive industry is constantly evolving, and carbon fiber is undoubtedly a game-changer in this ever-changing landscape.

Frequently Asked Questions (FAQs):

What are the advantages of using carbon fiber in cars?

Answer: Carbon fiber is lightweight yet strong, which improves fuel efficiency and enhances the overall performance of cars. It also adds a sleeker touch to the appearance of automobiles.

What parts of cars are made of carbon fiber?

Answer: Initially, carbon fiber was used in smaller parts and components of high-end cars and supercars, but now it is also being used in body construction. Carbon fiber is increasingly being used in electric cars as well.

Are carbon fiber cars more expensive than traditional cars?

Answer: Yes, carbon fiber cars are generally more expensive than traditional cars. However, with advances in technology and faster manufacturing processes, we can expect to see more widespread use of carbon fiber in mainstream automobiles.

How does the use of carbon fiber impact the environment?

Answer: The use of carbon fiber in cars can improve fuel efficiency, which leads to reduced carbon emissions. However, the production of carbon fiber is energy-intensive and can have environmental impacts. Therefore, it is important to ensure sustainable production practices.

Can carbon fiber be recycled?

Answer: Carbon fiber can be recycled, but it is a complex process that requires specialized equipment. Therefore, it is important to promote the use of sustainable production practices and responsible recycling of carbon fiber components.